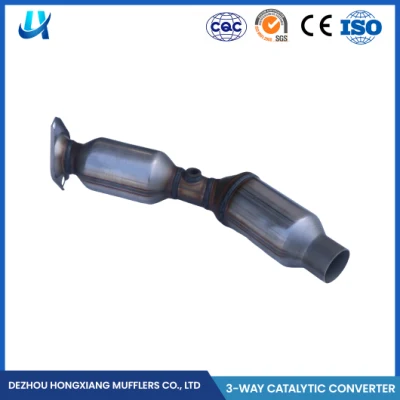

Auto Engine Parts DPF Silicon Carbide Diesel Particulate Filter and Docdiesel Oxidation Catalyst for Diesel Aftertreatment System

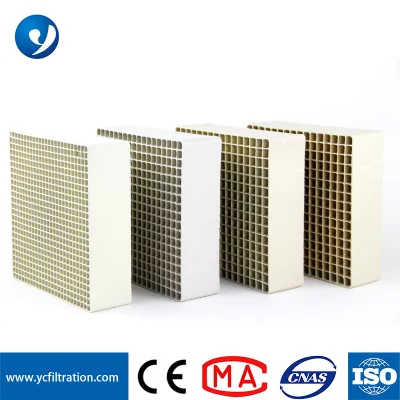

Product Description Honeycomb ceramic is a new type of ceramic product with a honeycomb-like structure developed in thep

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | DPF DOC |

| Main Market | Europe |

| Color | Grey,White(General) |

| Engine Type | Gas/Diesel |

| Discharge Standard | Euro V Euro VI |

| Transport Package | Paper/Wooden Carton with Pallet |

| Specification | 267*152.4mm |

| Trademark | HOONPAI |

| Origin | China |

| HS Code | 6909190000 |

| Production Capacity | 500000pieces/Month |

Product Description

Honeycomb ceramic is a new type of ceramic product with a honeycomb-like structure developed in thepast 30 to 40 years.From the earliest use in the purification of small automobile exhaust, it is widely used inchemical, electric power,metallurgy,petroleum, electronic appliances, machinery and other industries, and itis becoming more and more extensive, and its development prospects are considerable.Honeycomb ceramic is a new type of ceramic product with a honeycomb shape.It is the key component of the regenerative burner, which is widely used in the regenerator, heat exchanger and other equipmentin the chemical, metallurgical and environmentalprotection industries.as important and effective measure of dealing with energy and environment. It is widely used inthe purification of vehicles. The products aremeshed with round and oval, and the number of holes is much larger.This is especially important as a catalytic carrier, and the channels of pores are straight and parallel each other.This structure reduces the resistance of passing air and enhances the heat exchange efficiency ofevery channel.

Other Pictures for Honeycomb Ceramic

Material

Honeycomb ceramics can be made from a variety of materials. The main materials are: cordierite, mullite, aluminumtitanate, activatedcarbon, silicon carbide, activated alumina, zirconia, silicon nitride and cordierite-mullite,cordierite-aluminum titanate and other composite substrates.

Product Advantages

1.Excellent thermal shock resistance.2.Unique cellular designs make metal liquid reducing the vortex and raducing the bubbles in the casing;3.Accurate extrusion die make product quality extremely stable and consistency;4.Obvious filter effect;5.Improving the casting surface performance and improving the density of the casting;6.Improving metal structure and quality prolong the working life of the casting;7.Good chemical stability,not affected by of melted metal,no change in its chemical compound;8.Precise dimension and can be used in pruduction line automatic filter mounting

Product Specification

| Honeycomb ceramics | Diameter(mm) | Height(mm) | Quantity of channels |

| DPF | Φ143.8 | 203 | |

| Φ190.5 | 152.4 | ||

| Φ190.5 | 203 | ||

| Φ190.5 | 254 | ||

| Φ241 | 152.4 | ||

| Φ241 | 203 | ||

| Φ241 | 254 | ||

| Φ267 | 203 | ||

| Φ267 | 228 | ||

| Φ267 | 254 | ||

| Φ267 | 305 | ||

| Φ286 | 254 | ||

| Φ286 | 305 | ||

| Φ305 | 203 | ||

| Φ305 | 254 | ||

| Φ305 | 305 | ||

| Φ330 | 254 | ||

| Φ330 | 305 | ||

| Φ240 | 76.2 | ||

| Φ240 | 101.6 | ||

| Φ240 | 152.4 | ||

| Φ266.7 | 76.5 | ||

| Φ266.7 | 101.6 | ||

| Φ266.7 | 152.4 | ||

| Φ286 | 76.8 | ||

| Φ286 | 101.6 | ||

| Φ305 | 152.4 | ||

| Φ305 | 101.6 | ||

| Φ305 | 152.41 | ||

| Φ330 | 76.12 | ||

| Φ330 | 101.6 | ||

| Φ330 | 152.4 | ||

| Substrate | Φ143.8 | 101.6 | |

| Φ143.8 | 152.4 | ||

| Φ190.5 | 76.2 | ||

| Φ190.5 | 101.6 | ||

| Φ190.5 | 152.4 | ||

| Φ241.2 | 101.6 | ||

| Φ241.2 | 152.4 | ||

| Φ267 | 101.6 | ||

| Φ267 | 152.4 | ||

| Φ286 | 101.6 | ||

| Φ286 | 152.4 | ||

| Φ305 | 101.6 | ||

| Φ305 | 152.4 | ||

| Φ330 | 101.6 | ||

| Φ330 | 152.4 |

Working principle of DOC + CDPF + SCRThe Catalytic Converter applies to the following

Packing pic

Production Line of Honeycomb Cremic

Our Company

We are a group of manufacturing, machining, and distributor in auto engine parts. We are growing to be one of the biggest wholesaler and distributor of auto parts in South China Guangdong province.