Waterproof 100 200 300 400 600 Cpis Cordierite DPF/Silicon Carbide Cdpf/Vanadium-SCR/Fe-SCR /Cu-SCR Catalyst Oxidation Purification of Diesel Engine Exhaustgas

Product Introduction RFQQ:What are your main products?A:Our main products are diesel engine exhaust after-treatment syst

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Catalyst - CDPF/DOC/SCR/VOC |

| Certification | ISO9001, CE, E-Mark, RoHS, TS16949 |

| Standard Component | Standard Component |

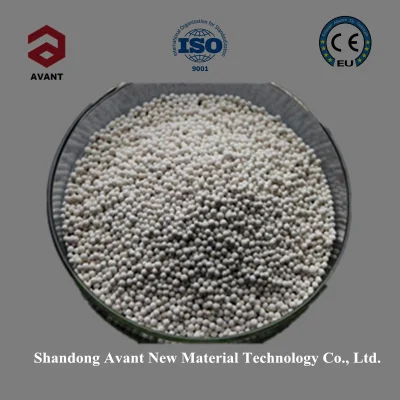

| Material | Vanadium, Cu-Zeolite, Fe-Zeolite, Precious Metal |

| Type | Catalyst - Cdpf/Doc/SCR/Voc |

| Mesh Number | 50 100 150 200 300 400 600 Cpsi |

| Shape | Square or Cylindrical |

| Catalyst Type | Cdpf/Doc/SCR/Voc |

| Cdpf Type | Cordierite DPF/Silicon Carbide Cdpf |

| SCR Type | Vanadium-SCR/Fe-SCR /Cu-SCR |

| Meet Emission Standards | Euo V, Euo VI, Non-Road Euo IV and Above Emission |

| Diameter | 143.8~330.2 (mm);118.4~330.2(mm) |

| Height | 76.2~177.8(mm);76.2~152.4(mm) |

| Size | Special Size Can Be Customized |

| Price | Receive Bargaining |

| Advantages1 | Reduce Pm/Pn Emissions |

| Advantages2 | Oxidation Purification of Diesel Engine Exhaustgas |

| Main Application Scope | Wastegas Conversion Catalytic Combustion Treatment |

| Transport Package | Waterproof Film, Carton Packing, Wooden Cases |

| Specification | customized |

| Trademark | Kailong |

| Origin | Jiangsu Wuxi |

| HS Code | 842132 |

| Production Capacity | 20000 Pieces/Year |

Product Description

Product Introduction| CDPF | Cordierite DPF | Diameter:143.8~330.2(mm) Square: 150*150 | Height:76.2~177.8(mm) Square:150mm,200mm,300mm | 200CPSI,300CPSI | Wall flow structure is adopted to capture particulate matter in diesel exhaust.Reduce PM/PN emissions to meet EUO V and VI of road diesel engines,Non road EUO IV and above emission standards. |

| Silicon carbide CDPF | Diameter:143.8~330.2(mm) | Height: 76.2~177.8(mm) | 200CPSI,300CPSI |

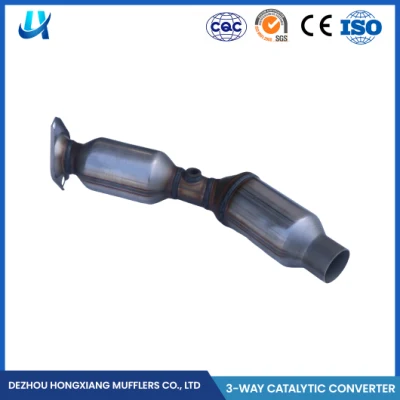

| DOC | Diameter: 118.4~330.2(mm);Square: 100*100,150*150 | Height: 76.2~152.4(mm);Square:50mm,100mm,150mm,200mm,300mm | 200CPSI,300CPSI, 400CPSI,600CPSI | Oxidation purification of HC, CO and SOF in diesel engine exhaust gas.By oxidizing NO to NO2 in the exhaust gas of diesel engine,Passive regeneration of CDPF was realized by de-oxidizing SOOT.By directly oxidizing fuel HC,Increase CDPF inlet temperature, Realize active regeneration of CDPF.Suitable for road diesel engine EUO V, EUO VI,Non road EUO IV and above emission standards |

| Catalyst - Vanadium SCR | Diameter: 118.4~330.2(mm) Square: 100*100,150*150 | Height: 76.2~152.4(mm) Square:50mm,100mm,150mm,200mm,300mm | 200CPSI 300CPSI 400CPSI | It is mainly used to purify NOx in diesel engine exhaust by urea-SCR technology. It is divided into V-SCR catalytic converter and molecular sieve SCR catalytic converter. V-scr catalytic converter can meet the requirements of diesel engine road EUO IV,EUO V and EUO IV emission standards for non-road small and medium power diesel engines; Molecular sieve SCR catalytic converter is mainly used in diesel engine road EUO VI and Non-road EUO VI and above emission standards. |

| Catalyst - Cu SCR | Diameter: 118.4~330.2(mm) Square: 100*100,150*150 | Height: 76.2~177.8(mm)Square:50mm,100mm,150mm,200mm,300mm | 200CPSI 300CPSI 400CPSI 600CPSI | |

| Catalyst - Fe SCR | Diameter: 118.4~330.2(mm) Square: 100*100,150*150 | Height: 76.2~177.8(mm)Square:50mm,100mm,150mm,200mm,300mm | 200CPSI 300CPSI 400CPSI 600CPSI |

| VOC | 100*100(mm) 150*150(mm) | 50~300(mm) | 50CPSI 100CPSI 200CPSI 300CPSI | Using high specific surface modified alumina and high performance rare earth oxygen storage material as the second substrate,With precious metals Pt, Pd as the main active ingredient,The integral catalytic converter prepared by the method of high dispersion and uniform distribution,Through catalytic oxidation of all kinds of industrial volatile organic waste gas VOCs, to achieve industrial emission standards, mainly used in catalytic combustion treatment of food, chemical, printing, machinery, automobile manufacturing, petrochemical, organic chemical, pharmaceutical chemical industry emissions containing carbon monoxide, aromatic hydrocarbons, hydrocarbons and oxygen-containing derivatives, etc toxic and harmful organic waste gas. |

RFQQ:What are your main products?

A:Our main products are diesel engine exhaust after-treatment system(SCR system, DPF system etc.), and parts(Urea Pump,Urea Nozzle,Catalyst Converter, Sensor etc.) Q:Do you have after-sale service?

A:"Customer first" is the core principle followed by our company, and it is also the super criteria adhered by our after-sales service staff. We have established comprehensive after-sales service network. With headquarter in Wuxi, we have branch offices Shanghai, Beijing, Changchun, Zhengzhou, Guangzhou, Changsha, Xuzhou and authorized service center throughout the country. We also provide 24 hours free hotline for customerswith premium quality and efficient after-sales service

Q:I wonder if you can provide free samples?

A:Whether the sample is free depends on the content of the sample and can be decided after discussion

Q:What product certifications do you have?

A:ISO9001, CE, E-Mark, RoHS And TS16949Q:What is the delivery time of your product?

A:Generally, it is about 1 month. The delivery time depends on the quantity of the order.

Related Products

-

![Honeycomb Ceramic Substrate Catalyst Used for Car Exhaust Pipe]()

Honeycomb Ceramic Substrate Catalyst Used for Car Exhaust Pipe

-

![Kailong Original 12V/24V Waterproof Engine Parts -40~850º C Nitrogen Oxygen Sensor/Nox Sensor Used for Emission Control]()

Kailong Original 12V/24V Waterproof Engine Parts -40~850º C Nitrogen Oxygen Sensor/Nox Sensor Used for Emission Control

-

![Oxidation Purification of Diesel Engine Exhaustgas Catalyst Assembly Doc Cdpf SCR Voc Substrate Catalyst]()

Oxidation Purification of Diesel Engine Exhaustgas Catalyst Assembly Doc Cdpf SCR Voc Substrate Catalyst

-

![Automobile & Motorcycle 3 Way Catalyst Manufacturers Three Way Catalytic Converter with Ceramic Honeycomb Substrate & Metallic Carrier Catalyst]()

Automobile & Motorcycle 3 Way Catalyst Manufacturers Three Way Catalytic Converter with Ceramic Honeycomb Substrate & Metallic Carrier Catalyst