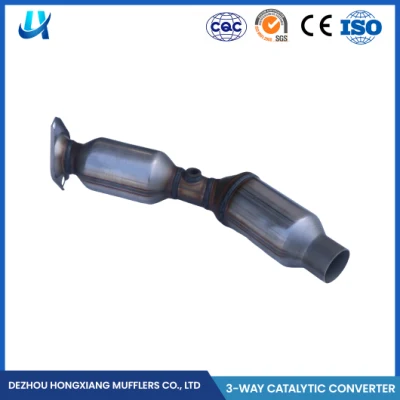

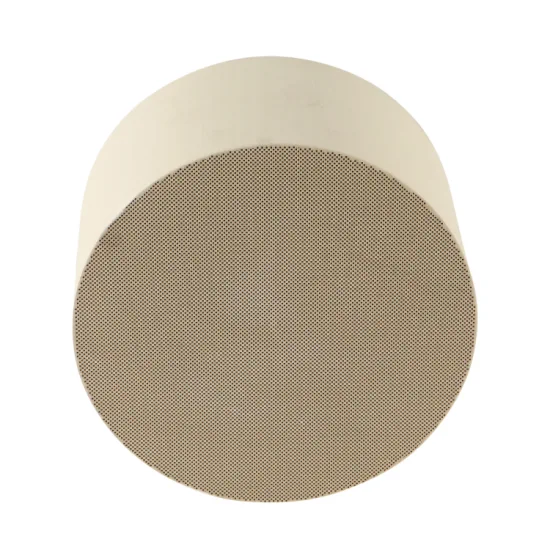

Intumescent Mat Catalytic Converter Support Mat

LUYANGWOOL ® Ceramic Fiber Blanket / RCF Blanket Luyangwool ® ceramic fiber blanket is high strength, needled insulating

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Luyangwool |

| Usage | High Temperature Insulating Material |

| Temprature Classification | 1600℃, 1500℃, 1400℃, 1260℃, 1050℃ |

| Chemical Composition: | SiO2, Al2O3.SiO2, Al2O3 |

| Shape | Ceramic Fiber Blanket |

| Kind | Ordinary Ceramic Fiber |

| Province | Shandong |

| Name | Ceramic Fiber Blanket |

| Product | Thermal Insulation Ceramic Fiber Blanket |

| Raw Material | Ceramic Fiber |

| Manufacturer | Luyang |

| Transport Package | Carton/Bag/Pallet |

| Specification | 12.5/25mm/50mm |

| Trademark | Luyangwool |

| Origin | China |

| HS Code | 68061010 |

| Production Capacity | 500, 000 Tons |

Product Description

LUYANGWOOL® Ceramic Fiber Blanket / RCF Blanket

Luyangwool® ceramic fiber blanket is high strength, needled insulating blanket that is made from Luyangwool® ceramic fiber bulk. The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating.

Luyangwool® ceramic fiber blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. Luyangwool® ceramic fiber blanket can be folded, compressed and encapsulated to produce module.

Features

Excellent thermal shock resistance

Excellent thermal stability

High tensile strength

Low thermal conductivity

Low heat storage

Typical Applications

Pipe wrap

Furnace and kiln back-up insulation

Chimney insulation

Annealing furnace linings

Process heater linings

Typical Parameters

Description | LUYANGWOOL® STD BLANKET | LUYANGWOOL® HP BLANKET | LUYANGWOOL® HA BLANKET | LUYANGWOOL® HZ BLANKET | |||||

Classification Temperature (ºC ) | 1260 | 1260 | 1350 | 1430 | |||||

Chemical Composition (%) | |||||||||

Al2O3 | ≥43 | ≥44 | ≥52 | ≥35 | |||||

SiO2 | ≥54 | ≥55 | ≥47 | ≥49 | |||||

ZrO2 | - | - | - | ≥15 | |||||

Color | White | White | White | White | |||||

Shot Content (%) | ≤15 | ≤15 | ≤15 | ≤12 | |||||

Density (kg/m³) | 64 | 96 | 128 | 96 | 128 | 96 | 128 | 96 | 128 |

Tensile Strength (kPa) | 30 | 50 | 70 | 50 | 70 | 50 | 70 | 50 | 70 |

Permanent Linear Shrinkage (%) | 1000ºC x 24h ≤2.5 | 1100ºC x 24h ≤2.5 | 1200ºC x 24h ≤3.0 | 1350ºC x 24h ≤3.0 | |||||

Thermal Conductivity (W/m·K) | |||||||||

200ºC | 0.07 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

400ºC | 0.12 | 0.11 | 0.10 | 0.11 | 0.10 | 0.11 | 0.10 | 0.11 | 0.10 |

600ºC | 0.20 | 0.19 | 0.18 | 0.19 | 0.17 | 0.18 | 0.16 | 0.16 | 0.15 |

800ºC | 0.30 | 0.23 | 0.20 | 0.23 | 0.20 | 0.22 | 0.20 | 0.21 | 0.19 |

1000ºC | 0.40 | 0.32 | 0.27 | 0.31 | 0.26 | 0.30 | 0.26 | 0.30 | 0.26 |

![[Qisong] Non-Intumescent Mat for Sealing Catalytic Converter](/uploads/s/c26f838e2b094ba2866d4cfaeb0a636b.webp)

![[Qisong] Non-Intumescent Mat for Ceramic Substrate](/uploads/s/b2465b8834104e3bb4bc7647fb3a9f91.webp)