Honeycomb Ceramic Monolith Catalyst Support for Automobile Car Cordierite Material

Package size per unit product 10.00cm * 10.00cm * 10.00cm Gross weight per unit product 1.000kg Honeycomb Substrate , al

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Sanhe CS HC |

| Transport Package | Hard Carton or Wooden Carton with Pallet |

| Specification | Cordierite/Alumuina/ Carbide |

| Trademark | Sanhe |

| Origin | Jiangxi Province, China |

| HS Code | 6909110000 |

| Production Capacity | 800, 00pieces/Month |

Packaging & Delivery

Package size per unit product 10.00cm * 10.00cm * 10.00cm Gross weight per unit product 1.000kgProduct Description

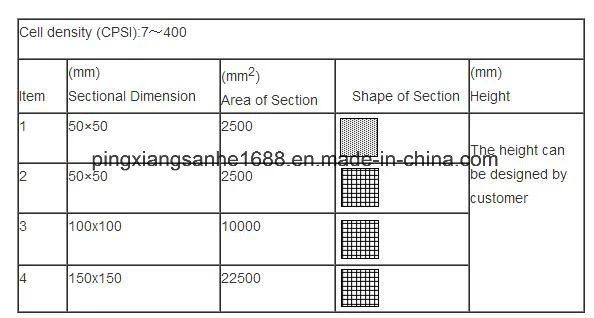

Honeycomb Substrate, also called support, is one of the components of the supported catalyst. The catalytically active component is supported on the surface of the carrier, the carrier is mainly used to support the active component, so that the catalyst has a specific physical property, and the carrier itself generally does not have catalytic activity.Honeycomb substrate is mainly used in the automotive and other high-temperature process exhaust. The main material is cordierite, after coated the catalyst, catalytic conversion of the exhaust, so as to achieve the national emission standards. It has characteristics of large surface area, small expansion coefficient, high strength, high water absorption, and good matching with the catalytic active component, heating up fast and so on.Honeycomb ceramic as a Honeycomb Substrate is an efficient carrier and can achieve good results in specific applications. For example: photo-catalysis, fresh air system, ventilation systems.Product size can be customized according to customer needs.Characteristics:1. Large specific surface area: to ensure full access to the exhaust gas with the catalyst;2. Stable water absorption: to ensure the catalyst evenly firmly attached to the surface of the honeycomb substrate.3. Warm-up: after start-up the engine, the temperature of the carrier can reach the catalyst activation temperature in the shortest possible time.4. Low exhaust resistance: the engine's exhaust resistance is small, to ensure that doesn't affect the engine performance.5. High strength: the operating environment of the honeycomb substrate is in the bumpy car, so the honeycomb substrate must be high strength without being external damage.6. Good assembly: the carrier is an exhaust assembly parts, only good appearance and precise dimensions can ensure perfect assembly.Technical Data Sheet:

| Name | Index | Tolerance Range |

| Wall Thickness | 0.17mm | 0.03mm-0.02mm |

| Volume Weight | ≤460G/L | ±60G/L |

| Outside Dimension | 25-100mm | ±1mm |

| 100-15mm | ≤±1% | |

| Perpendicularity | ≤1.0%(height) | |

| Depth of Parallelism | ≤1.0%(height) | |

| Mesh Number | 200mesh, 300mesh, 400mesh |

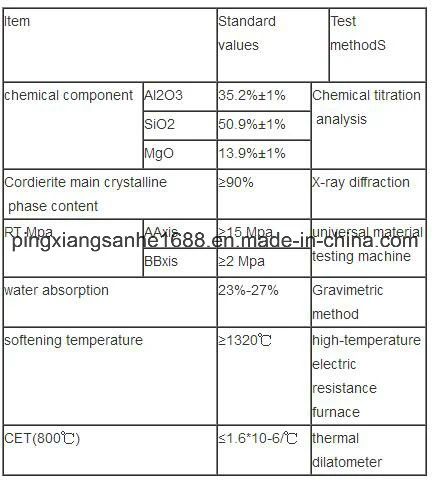

Physical and Chemical Properties:

| Name | Unit | Index | |

| Chemical Composition | Al2O3 | % | 35.1±1.6 |

| MgO | % | 13.5±1.5 | |

| SiO2 | % | 50.0±1.8 | |

| Compression Strength | A-axis | Mpa | ≥15.0 |

| B-axis | Mpa | ≥3.0 | |

| C-axis | Mpa | ≥0.15 | |

| Coefficient of Thermal Expansion (20-800ºC) | ºC | ≤1.5*10-6 | |

| Soften Temperature | ºC | ≤1410 | |

| Thermal Shock Resistance | ºC | ≤550ºC | |

| Water-absorbingrate | % | 24±4% | |

| Cordierite CrystalContent | % | ≥90 | |

| Open Area | % | ≥70% | |

About us

Pingxiang Sanhe Ceramics lies in Pingxiang city, Jiangxi province, which belongs to one of the five ceramic production export bases in China. The company is a private technology share ceramics manufacturing enterprise founded in 2004. We specialize in honeycomb ceramic plates, honeycomb ceramics heat accumulators, honeycomb ceramic honeycomb substrates, ceramic foam filter and other producing energy conservation and environmental protection series ceramic products.

Sanhe Ceramics has successfully passed all kinds of certifications such as ISO9001 ISO14001, OHSAS18001 and so on, as well as established perfect quality control system and quality assessment system. Our company has been strictly controlled the whole manufactring system from production planning, processing control to maintenance of equipment as well as from raw material warehousing to quality test of finished products, We offer Stable and qualified products to customers from all over the world. Superiority, uniformity and environmental friendliness of its quality has gained great reputation among all customers. We obey the research and development design production idea of specialization, standardization, internationalization and technicalization, striving to make the products of the company more perfect with stronger customer base.

Sanhe ceramics keeps the faith of "First impression is the last impression" and provides the best quality and comfortable service to all the buyers, No matter the deal is big or small, we are warmly welcome your coorperation. Any inquiries pls contact with us!

Related Products

-

![Professional Car Metallic Three Way Mini Direct Fit Catalytic Converter for Toyota Prius]()

Professional Car Metallic Three Way Mini Direct Fit Catalytic Converter for Toyota Prius

-

![Selective Catalytic Reduction SCR Honeycomb Ceramic Substrate Catalyst for Engine]()

Selective Catalytic Reduction SCR Honeycomb Ceramic Substrate Catalyst for Engine

-

![Auto Parts Catalyst Universal Style Exhaust Catalyst Three Way Catalytic Converter with Euro V for All Cars]()

Auto Parts Catalyst Universal Style Exhaust Catalyst Three Way Catalytic Converter with Euro V for All Cars

-

![Gaoxinsens Auto Parts High Quality Nitrogen Oxygen Sensor Nox Sensor for Scania_ 5wk97400 2294290]()

Gaoxinsens Auto Parts High Quality Nitrogen Oxygen Sensor Nox Sensor for Scania_ 5wk97400 2294290