Diesel Exhaust Device Particulate Filter Clean Machine for Kingkar DPF 6.0

DPF cleaner diesel particulate filter cleaning machine DPF cleaning machine parameter: DPF cleaning machine working prin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | DPF 6.0 |

| Main Market | Europe |

| Brand Name | Kingkar DPF Cleaning Machine |

| Usage | Auto Industry |

| Machine Type | Water Flushing and High-Pressure Purging Work |

| OEM | Available |

| Working | Continuous |

| Liquid Temperature (ºC) | 55-60 |

| Tank Pressure | 8 |

| Function | Clean DPF and Unblock Mesh |

| Voltage/Power | 380V/220V Three-Phase Four-Wire System |

| Power Resource/Fuel | Electric/Water |

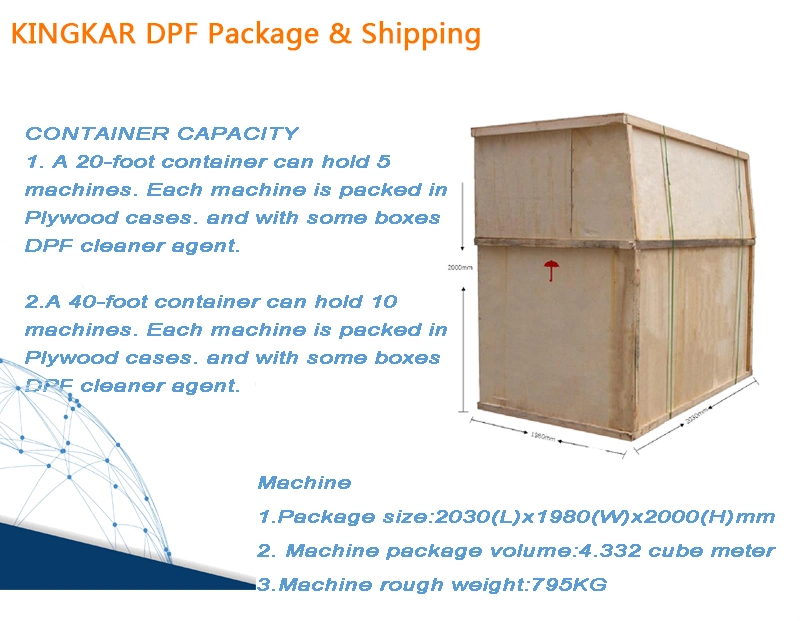

| Transport Package | Standard Wooden Box |

| Specification | CE, ISO9001 |

| Trademark | HHO |

| Origin | Hunan. China |

| HS Code | 8479899990 |

| Production Capacity | 500 Sets a Month |

Product Description

DPF cleaner diesel particulate filter cleaning machine

DPF cleaning machine parameter:

| Voltage (AC) | 380V three-phase four-wire system | Equipment Size(MM) | cleaning room:850*900*1750 DPF machine:800*800*1050 |

Maximum Power (KW) | 12.8 | Equipment Weight (KG) | 368 |

Liquid Temperature (ºC) | 55-60 | Safety Warning | The chassis ground wire shelf must be reliably connected to the ground. |

Gas Tank Capacity (L) | 25 | Tank Pressure (KG) | 8 |

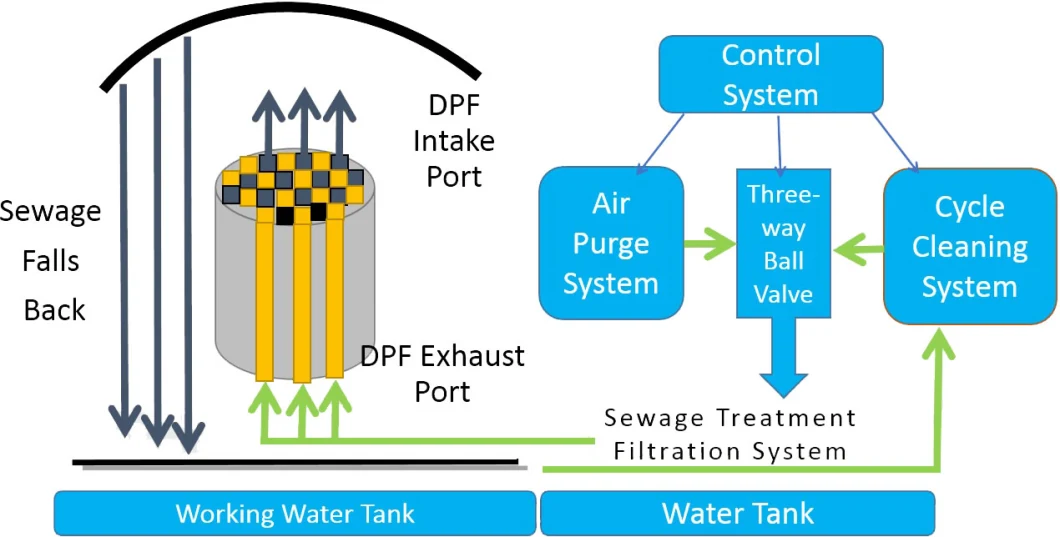

DPF cleaning machine working principle:

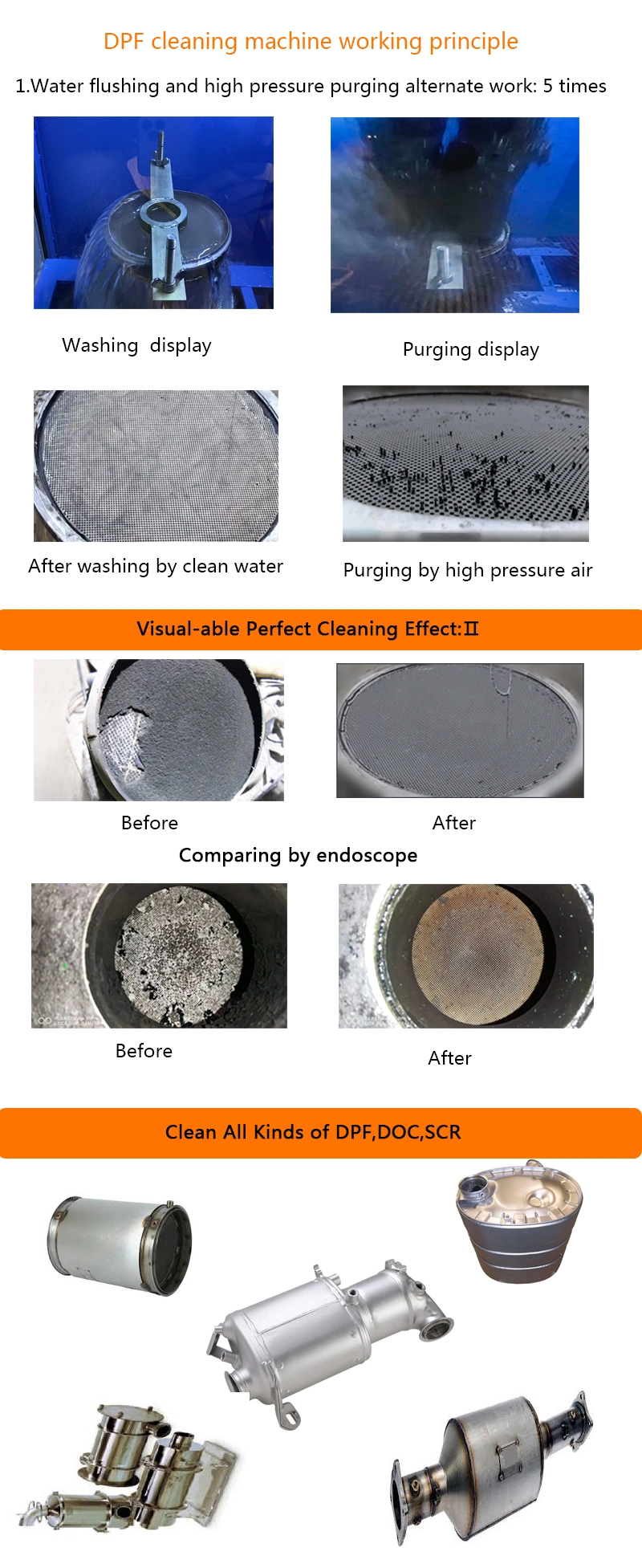

Simply, it is water flushing and high pressure purging alternate work.

The high-pressure air in the high-pressure gas storage tank is released instantaneously. Using the top water of the air, the compressed water is generated to generate potential energy, and the blockage inside the honeycomb carrier is pushed out instantly

1. After the circulating water is flushed, the bottom of the DPF and the honeycomb mesh are filled with water.

2. The high-pressure gas in the high-pressure air storage tank is instantly released, and the water under pressure by the high-pressure air will instantly push out the hydrogen sulfate and ammonia bicarbonate composite blockage adsorbed inside the honeycomb mesh.

This process will cycle three times. So that can remove all the blockage out from filter. It can reach nearly 100% cleaning efficiently.

Schematic Diagram of Working Principle:

KINGKAR DPF cleaning machine Comparing with other machines:

| Kingkar DPF Cleaning Machine | Other machines | |

| Feature | The high-pressure air in the high-pressure gas storage tank is released instantaneously. Using the top water of the air, the compressed water is generated to generate potential energy, and the blockage inside the honeycomb carrier is pushed out instantly. Simply, it is water flushing and high pressure purging alternate work. | Only using water or air purging or burning it.need to move the filter from one work-top to another work-top. |

| Difference | 1. Can total Removal of oil residuals, PM10, cerium residuals. 2. Cleaning different types of particulate filters and catalyst efficiently(SCR and DOC) 3.Safety for all the filters. 4.Preservations of the noble metals of the DPF. 5. Processing water always clean because of an efficient filtration system: no need to change the water. | 1.At most clean DPF 70% using water.because the blockage is insoluble in water. 2.Lower efficiency on the very dirty filter(oil)and big-sized filters 3.Risk of damaging the filter due to the high temperature by heating and burning. 4.High water consumption |

| Work time | Cleaning time only 60 mins. | 3-24hours |

| Cost | Only 1 set of machine enough. | 2 or 3 or 4 machines. |

To be the Sole distributor you will get the following supporting:

1.Best price----Distributor price for DPF6.0 cleaner machine and DPF cleaning agent;

Authorized you being Kingkar sole distributor---in your country

2. Promotion material -----advertisement design and printing free for you. Such as flyers and rolled banners;

3. New website---we will build a new website for you to do promotions;

4. Open Facebook page--- for you free and we pay for the daily cost;

5.Technical training---one to one after service from our professional service team;

6. Free spare parts for maintenance---no worry about the after selling service, we will provide the spare parts to our distributor for two years

Welcome to contact us and become our exclusive agent!!!

Related Products

-

![Genuine Diesel Engine Qsm11 Doser Pump 5273338 Urea Pump 24V 4931694]()

Genuine Diesel Engine Qsm11 Doser Pump 5273338 Urea Pump 24V 4931694

-

![Avant Diesel Oxidation Catalyst Factory China Isomerization Catalystlong Service Life C4 C5 C6 Low Temperature Light Hydrocarbon Isomerization Catalyst]()

Avant Diesel Oxidation Catalyst Factory China Isomerization Catalystlong Service Life C4 C5 C6 Low Temperature Light Hydrocarbon Isomerization Catalyst

-

![Ocsun Mullite Foam China Diesel Particulate Regeneration Factory Ceramic Honeycomb Monolith Diesel Particulate Filter DPF Filters Skoda Audi A3]()

Ocsun Mullite Foam China Diesel Particulate Regeneration Factory Ceramic Honeycomb Monolith Diesel Particulate Filter DPF Filters Skoda Audi A3

-

![Alumina 25 Cell, 40 Cell, 43 Cell, 50 Cell, 60 Cell Honeycomb Ceramic Heat Exchanger]()

Alumina 25 Cell, 40 Cell, 43 Cell, 50 Cell, 60 Cell Honeycomb Ceramic Heat Exchanger